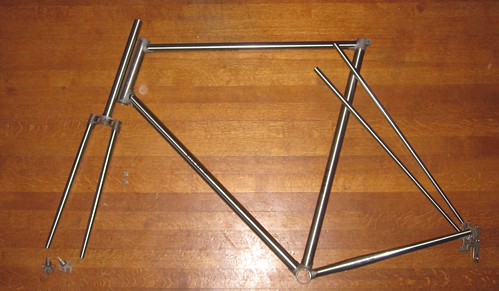

Ready to build a couple of frames

Last year I started and got about 60% of the way done with the 3-speed project frame before stalling out trying to decide what to do for a rear end jig, and it’s been sitting in the basement waiting for me to glue on the chainstays and finish the fork since then. But now, here’s another frame I need to build as well (this is a frame for an east coast randonneur, so it’s going be all lowtrailplaneyflexylighttubing700c; 8/5/8 main triangle, 9/6 fork blades, skinny tubed rear triangle (the only bicycle I had that planed in the traditional BQ fashion – the kit bike, if I let the tires get too low, planes, but I don’t really want a pair of tubeless tires flexing side-to-side under load – was an Ahearne that I owned for a couple of months; it had paired seatstays – two super-skinny ones per side – and if I got it up to about 17mph it would simply vanish under me. It was a bit too big, a bit too blingy, slower than the midlifecrisismobile and born-again Trek, and when I had to pay a tax correction I flipped it for the purchase) so I suspect the small-tubed rear triangle will make this one plane like it’s going out of style.) So I might as well do both frames as a batch.

But since I’m making this frame for someone else (and it’s $270 worth of tubing, lugs, and castings) I can’t just do the sort of ad hoc jiggery I did on the front triangle of the 3-speed project frame, both triangles on the kit bike, and the mountainhack’s rear triangle. So what I’m planning on doing is getting a few feet of hardwood 2x4 (or some unit blocks; probably cheaper, and definitely square :-) and using hole saws (1", 1⅛“, and 1¼” to make them into support blocks that will hold the frame pieces 34mm above a flat surface for positioning and pinning/tacking the front triangle, and then 75mm above that flat surface for tacking the rear triangle onto the frame. This is also not a perfect solution; my personal bikes have really short headtubes and I’ll need to find some way to support them without setting the support blocks on fire (or melting them if I get a large chunk of aluminum and chew up the hole saws make it into support blocks as well.)

As a longer-term thing, I’d love to buy some 8020 extrusion and make a freestanding frame jig, but I think I’d need to get a metal lathe or (win the lottery so I could afford a) CNC mill to fab the various attachments I’d need to make it a workable jig. So the traditional flat surface (I have a chunk of granite countertop sitting in my bike mess that’s flat enough for framebuilding) and support block dealie is what I’m going to live with for now.